I apologize for not posting for so long. I’ve had a really hectic time since coming back from my crazy quilting adventure in Connecticut. The most immediate one, after the retreat, was to get ready for the BDEIG Seminar in Portland that would be held in June. Time was getting short and I had received my student lists for the two classes that I was presenting there. I had two full classes of 18 students each registered!I Wow! How exciting! I had a lot to learn in a short time to get ready to present my designs in the manner that I wanted.

Coming up with the ideas and sketching my designs has been the easiest part of the equation for me. Getting them stitched had taken time, but was creative and usually quite relaxing for me….at least when I’d left myself enough time to get them done….but that’s another issue. Tracing from my original sketches had been fine for my use. But now, I faced new challenges……cleaning up my designs to have them look professional and getting them screen printed on my fabric patterns for my classes.

One of my BDEIG friends, Loretta Holzberger, shared a lot of her knowledge by way of a booklet she had presented about Paint Shop Pro 8 a few years ago. But, I had done some research and had found a program that I thought I’d like better….the program seemed to have the ability to things easier….Corel Draw X5. So, I ordered it out, along with a Wacom Intuos pen tablet. Well….I hate to admit it, but less is more……the learning curve on Corel Draw was a little steep for my time limits, (not that I won’t pursue it more in the future), but I found my Paint Shop Pro 8 program…..which I, incidentally, already owned, but had never used it for these purposes…..worked the best for my needs!  I did love the Wacom pen and tablet, though! I’ve added a picture of it on the right. Really great for doing detailed work. Well, I learned all about raster and vector layers and how to manipulate the lines in my designs, etc. and to use all this new knowledge to clean up my designs and to print the transparencies I’d need to have screen prints made. I think they ended up coming out looking pretty professional, too!

I did love the Wacom pen and tablet, though! I’ve added a picture of it on the right. Really great for doing detailed work. Well, I learned all about raster and vector layers and how to manipulate the lines in my designs, etc. and to use all this new knowledge to clean up my designs and to print the transparencies I’d need to have screen prints made. I think they ended up coming out looking pretty professional, too!

Now, I had to figure out how to get them screen printed! Many of the BDE designers come up with their own designs, but have professional screen printers print their fabric patterns for them. This is the easiest solution…there is no hassle, no mess for the designer this way; but, you must print a specific number. Others, screen print their own and can print them as needed. I decided that I wanted to pursue that avenue. I remembered a process that I’d learned about at the Houston Quilt Expo years ago involving Photo-Ez Screen Printing Stencils and, being the hoarder that I am, still had the information about it in my files. I contacted the vendor that had demonstrated it in Houston, Ginny Eckley at www.photoezsilkscreen.com , and ordered some of the stencils. Well, her directions were wonderful. I made a simple lamp unit for exposing the emulsion in the sheets and I was ready to make my first silk screen stencil! Well, I have to admit….they were actually pretty easy to do and I felt they couldn’t have come out better! YeeHaw! The picture below actually shows them after I’d used them…that’s why they are darker in the center from the inks.

The picture below actually shows them after I’d used them…that’s why they are darker in the center from the inks.

Now, the next project was to print the actual designs on fabric. I had to find an ink that was water soluble and would wash out after the print was stitched and washed. Once I found that, I needed to thicken it before using it to screen print with. Many people use sodium alginate to thicken whatever medium they use to screen print, but Ginny had use shaving cream in Houston to thicken her dyes and inks. Would you believe it….shaving creme? So, off I went to get some inexpensive Barbosol to mix my ink with. Well, it worked wonderfully! Easy to find, it did the job perfectly, and it was easy to clean up! How much more could I ask for? Plus, the prints came out beautifully.

The detail was clean and clear and when I tested the finished prints for washability, they washed out great. They only needed to be soaked for a couple hours or so in plain water or even quicker if a tiny bit of liquid Biz was added to the water. I definitely breathed a sigh of relief!

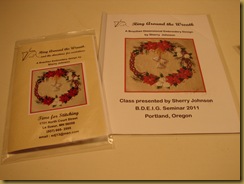

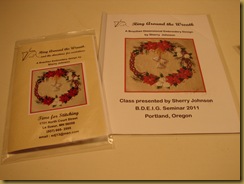

But, I wasn’t done yet. Now, I had to come up with, and print my directions. Taking Loretta Holzberger’s recommendation again, I ordered Microsoft Publisher and a book on how to use it and pressed forward. I’m excited to say that the results were good. Here are pictures of one of my class handouts and patterns:

I have to say that I loved teaching! I loved sharing my designs with my students and having the ability to help others learn more about this wonderful needlecraft. I hope all of my students learned a lot and enjoyed my classes. I, in turn learned a lot, too. I found ways that I could improve my written directions to make them easier to follow and have spent time editing them this summer. So, I now have them available for sale to the public.